In today’s competitive manufacturing landscape, data has become the most valuable asset in the factory. Yet in reality, most of this data is scattered and underutilised, preventing it from generating actual business value.

What is Digital Transformation for Manufacturers?

Industrial Digital Transformation is the process of making data the primary commodity of the organisation. This enables data-driven decisions by analysing historical data, understanding the present in real time, and predicting the future with actionable insights.

Pain Points of Industrial Digital Transformation in Thailand

“While Digital Transformation has become a serious agenda in global manufacturing, the reality is that local manufacturers in Thailand are still far from making data the primary commodity of their organizations.”

Profitable but Not Data-Driven

Many manufacturers in Thailand remain profitable, but their operations are not data-driven. Factories still rely heavily on Excel, manual logs, and paper-based reporting — far from the agility needed for modern decision-making.

AI Trend Is Pulling Them Forward

The global hype around AI predictions and Generative AI has reached manufacturing executives. Many want to adopt AI, but most lack the foundation of Industrial Data Engineering, the backbone required for scaling AI beyond pilots.

Three Components of the Manufacturing Data Backbone

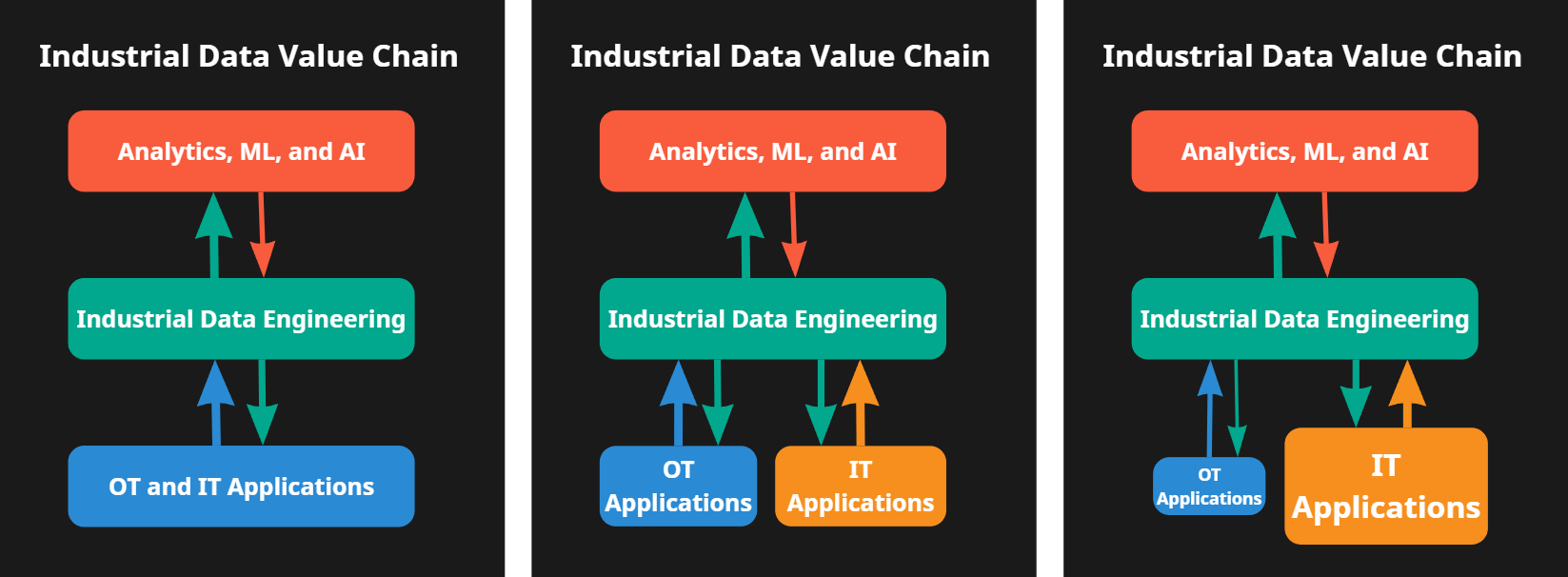

From the value chain perspective, digital transformation requires three critical components:

- OT & IT Applications – SCADA, MES, ERP, SAP, and other systems.

- Industrial Data Engineering – Unified Namespace (single source of truth), Historian (time-series database), and data pipelines.

- Analytics, ML, and AI – Prediction, optimisation, and Generative AI.

The problem: manufacturers often invest in Applications and AI, but neglect Industrial Data Engineering.

Mismatch in Investment: IT vs OT

Investment imbalance is striking:

- Large manufacturers in Thailand typically spend 50–200 million THB on SAP licenses and implementation.

- Yet, when it comes to OT systems like MES, many executives hesitate over a 5–15 million THB investment.

- Ultimately, at least half of the data required for decision-making and AI comes from the OT side. Without balanced investment, the data foundation remains incomplete.

The Missing Layer: Industrial Data Engineering

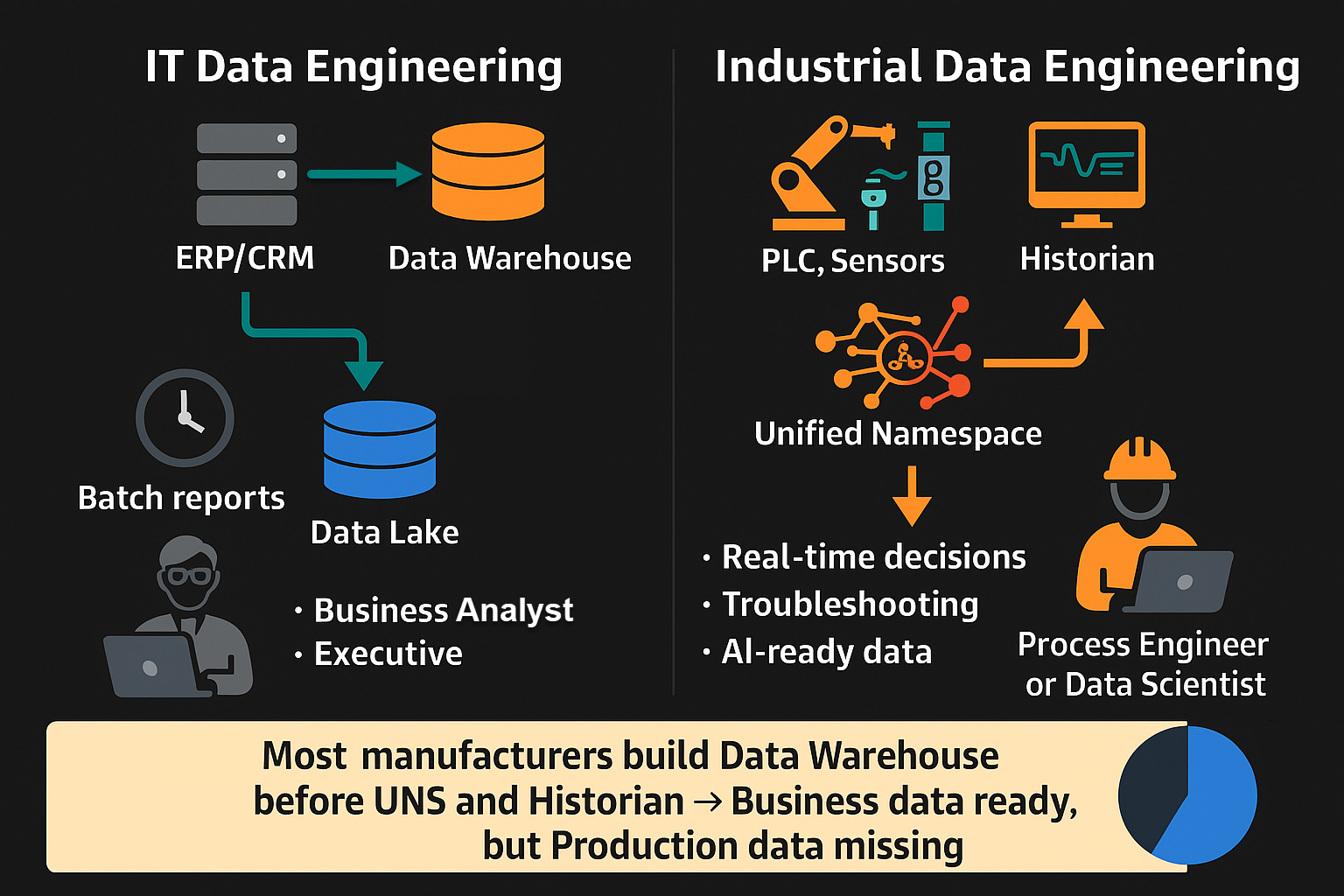

Most people associate “Data Engineering” with IT — building Data Warehouses and Data Lakes to analyse ERP, CRM, and business data.

But in manufacturing, what’s missing is Industrial Data Engineering, which consists of two critical elements:

- Unified Namespace (UNS) – the real-time single source of truth for factory data. It persists Parameters, KPIs, live events, and unfinished or recently finished transactions within the relevant time window (e.g., today, or the current shift). UNS provides the context required for MES, BI, or AI to work seamlessly.

- Historian – a specialised time-series database designed for process engineers. Unlike a generic TSDB, a historian is built to support troubleshooting and root cause analysis (downtime, quality deviations, process anomalies) directly on the factory floor.

Reality in Thailand

The truth is, most Thai manufacturing executives have never heard of Unified Namespace and have never properly practised time-series analysis for manufacturing. Instead, we see organisations with a Data Warehouse or Data Lake before they even have a UNS or Historian.

This occurs because IT data pipelines are typically built around ERP analysis, rather than production data. The result: ERP data is well-analysed, but production data is missing. Without production data, digital transformation efforts cannot scale.

IT Data Engineering vs. Industrial Data Engineering

| Aspect | IT Data Engineering | Industrial Data Engineering |

|---|---|---|

| Primary Source | ERP, CRM, Finance Systems | PLC, SCADA, MES, Sensors, OT Applications |

| Core Tools | Data Warehouse, Data Lake | Unified Namespace (UNS), Historian |

| Data Type | Business Data (orders, sales, finance) | Real-time Data, Time Series Data, Events, Transactions |

| Purpose | Reporting, Business Intelligence, KPI monitoring | Process monitoring, Root cause analysis, Troubleshooting, AI/ML readiness |

| Data Freshness | Batch (daily, weekly, monthly) | Real-time (seconds, minutes) |

| Users | Data Analysts, Finance, Executives | Process Engineers, Operators, Maintenance, Data Scientists |

| Pain if Missing | Business reporting not consolidated | AI cannot scale, operators can’t troubleshoot, decisions lack OT context |

Some Key Points

Industrial Digital Transformation is not about installing AI tools or buying new applications. It’s about building a solid data foundation through Unified Namespace and Historian so that both business data and production data are ready for AI. Without this, manufacturers will remain stuck in “Pilot Purgatory,” unable to scale AI initiatives into real business value.

This is the first part of my series “No BS Path to AI-Driven Manufacturing” — a straightforward look at how manufacturers can escape the hype and build AI-ready factories. In the next article, I’ll dive into practical implementation examples — from building a Unified Namespace to leveraging a Historian for real troubleshooting on the shop floor.

Stay tuned.